Beginning with the cave impressions of primitive man until reaching the most technologically advanced 3D printing, the history of printing has come a long way full of progress and satisfaction, accompanying the human being on his way to progress.

History of Printing

The printing press is a mechanical instrument that, by means of pressure applied to an inked surface, reproduces texts or forms on a surface that could be paper, cloth or another appropriate material. The invention and spread throughout the world of the printing press was one of the most important events in world history due to its contribution to the spread of communication and culture.

Evolution of printing

To talk about the history of printing, it is first necessary to talk about the history of printing. The first impressions found were achieved through the use of templates and date back to approximately thirty-five thousand years and they are handprints made by resting the hand on a wall and blowing some coloring substance, the oldest are found in Asia and Europe and of later dates on other continents.

Another ancient printing technique was stenciling, which consists of stamping the drawing found on a perforated stencil onto a surface by spreading ink over it using a brush, brush, or soaked cloth. The use of templates lasted for a long time, its highest level of sophistication being the Japanese katazome method used to print silk fabrics during the Edo period.

Between the first millennium BC and the early modern period, coin making was done by hammer minting, which consisted of placing a smooth sheet of metal of suitable weight between two engraved dies and then striking the upper die with a hammer.

Seals are a technique used in China since at least the Shang dynasty, during the second millennium BC. Seals were used to leave impressions on pottery. Evidence has been found that wooden seals containing up to one hundred and twenty characters were used in the northern dynasties. In the West, seals were used to mark documents with personal insignia normally engraved on a ring. This use began during the Roman Empire and spread during the Byzantine empires and the Holy Roman Empire.

Since ancient times, blocks of stone, clay and bronze have been used to capture patterns on fabrics. Archaeological evidence of block printing on fabrics dating back to XNUMX BC has been found in China.

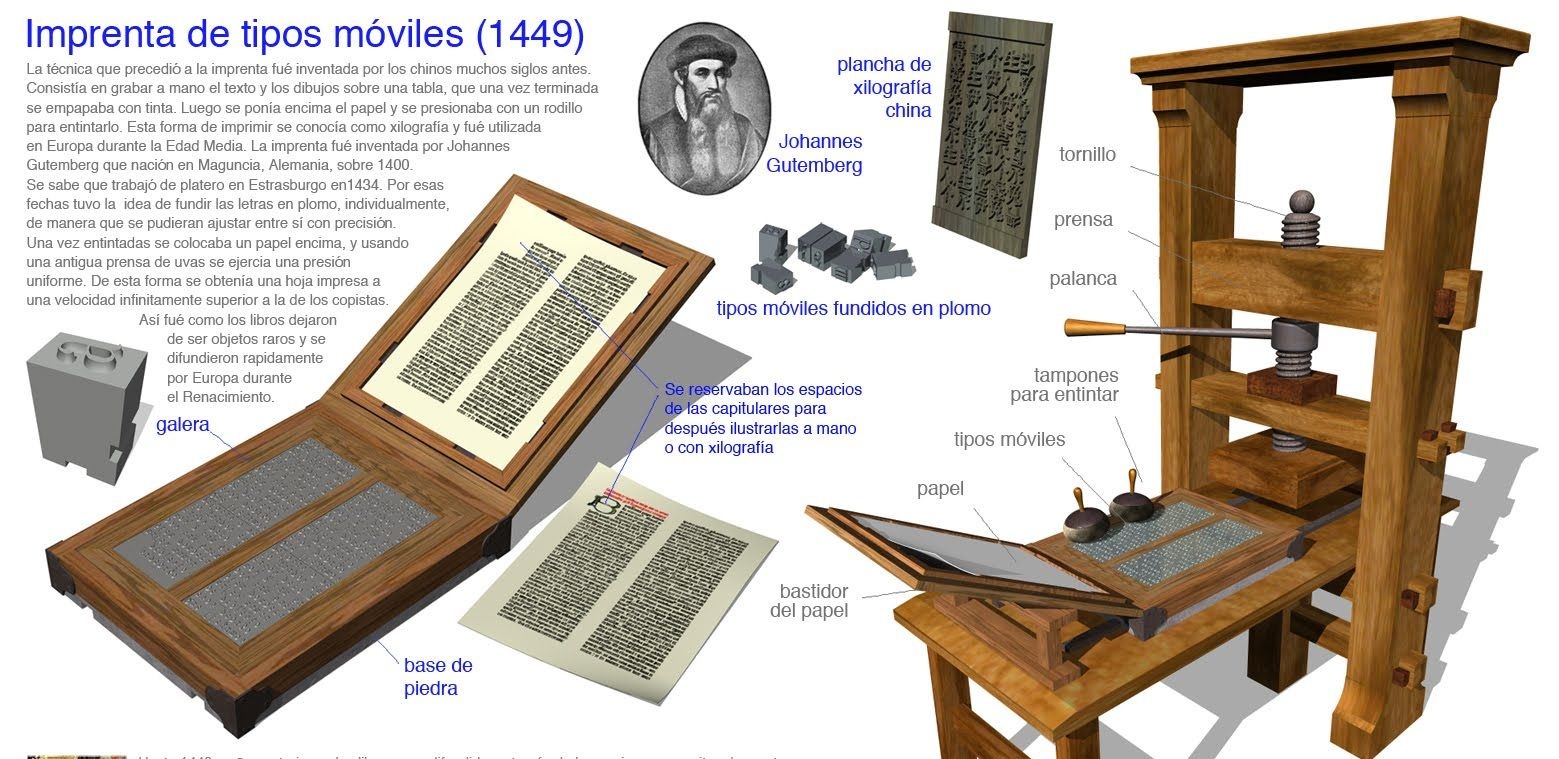

Printing using wood planks, known today as xylography, was the main technique used to print on paper. At first, this way of printing was widely used throughout East Asia to print on cloth, later, thanks to the influence of Buddhism, it began to be used to print on paper.

The printing press and its development

The history of printing begins with the Chinese inventor Bi Sheng who created the first method of printing using mobile phases made on pieces made of porcelain where Chinese signs were carved. Due to the large number of these signs used to make a Chinese script, the process was slow and cumbersome. Using the knowledge acquired by the Chinese in the handling of movable types, in the year 1234, during the Koryo dynasty, a set of movable types made of metal were created, but due to their low efficiency they had little use.

The books that were distributed before the year 1540 were copies made manually by copyists who were usually friars or monks whose only activity was to pray and make different copies that were almost always requests from the clergy or members of royalty. Many of these copyists could not read or write and limited themselves to imitating the signs of which they generally did not understand the meaning, which was important for the applicant since many of these texts contained subjects that were considered prohibited.

Between the XNUMXth century and the XNUMXth century, wooden blocks were used in Europe to publish pamphlets for advertising purposes or to send political messages, also labels or writings of a few pages. This was done by perforating the text and drawings on a wooden board that was then fastened to a wooden table impregnating it with ink with one of the colors that existed for the time (blue, red or black) then the paper was placed and by a roller fixed the color.

The wood wore out very quickly so the copies that could be printed were very limited. The paper was manufactured by the printer himself and each printer placed his own watermark on his paper with which he identified himself.

modern printing

Several preceding technological advances were combined and perfected by Johannes Gutenberg and by adding various inventions and innovations of his own he perfected the printing system. These advances, which contributed to the history of printing, were the creation of paper, the development of new inks, and xylography.

It also adopted the screw press, which had been used since the time of the Roman Empire for pressing grapes or olives for the manufacture of wine and olive oil, respectively. Gutenberg copied the basic idea to perfect printing. He modified the design so that the pressure on the paper was applied evenly, added a movable table with a flat enough surface so that the paper could be replaced quickly.

Gutenberg perfected the procedure by breaking up typographical layout and printing into two separate phases. He made the type pieces with a lead-based alloy that was quite suitable, to the point that it is still used today. After many attempts and experiments, Gutenberg came up with the formula for an ideal oil-based ink for high-quality printing with metal type, superior to the water-based ink used up to that time.

Gutenberg did a color test print for his Bible on some page headings in just a few copies. Very few copies of Gutenberg's Bible exist today, and far fewer are intact. In Spain there is a complete one in Burgos and another that only contains the New Testament is in Seville.

The printing revolution

A few years after the mechanical movable type printing press was invented, printing activity multiplied. From a single printing press that existed in the German city of Mainz, they multiplied in more than two hundred and seventy cities throughout Europe.

From the year 1480 the production of books became massive throughout the continent. In the year 1500 Western European printers had more than twenty million published copies, and by the following century it is estimated that more than two hundred million copies were published.

While in the Far East, using archaic printing methods, forty pages were produced daily, European printers were able to print more than three thousand six hundred pages per working day. The lowering of costs and the speed of printing allowed the publication of the first newspapers, which caused a revolution in the distribution of information to the public.

In the Iberian Peninsula, the history of printing began in the city of Segovia in 1472, being the authentic and main published work: the Sinodal de Aguilafuente. In New Spain the first printing press was established in Mexico in the year 1539 and in the viceroyalty of Peru the first printed book was The Christian Doctrine published in Lima in the year 1584.

Industrial printers

Although new printing press manufacturing materials had gradually increased printing efficiency, at the start of the Industrial Revolution the manual press designed by Gutenberg continued to operate virtually unchanged.

Lord Stanhope built an all-cast-iron printing press in 1800, which drastically reduced the pressure required and increased the printing area, multiplying the printing capacity to four hundred and eighty pages in one hour.

Friedrich Koenig designed a printing press similar to the manual printing press but connected to a steam engine, he also replaced the printing platform with a system of rotating cylinders. With the financing of Thomas Bensley and the assistance of the German engineer Andreas Friedrich Bauer he made his first printing press in 1811.

The Times of London acquired the first models of Koenig and Bauer's printing press in 1814, this press had the capacity to produce eleven hundred impressions daily. Manufacturers continued to refine their machine and achieved printing on both sides of the sheet of paper at the same time. The history of the printing press had a great boost since thanks to this the production of newspapers accelerated and increased its mass use even more.

rotary press

The American Richard M. Hoe invented in 1843 the rotary printing press powered by steam which allowed the printing of millions of copies in one day. In the year 1863, the inventor of the United States William Bullock improved the rotary printing press by adding a system for feeding the paper through the use of paper rolls, avoiding the slow process of manual feeding. Thanks to this innovation, the printing press was able to print up to twelve thousand sheets per hour with other improvements incorporated later, the speed was increased by printing thirty thousand sheets.

Offset printing

Offset printing is a printing technology that involves the application of a fat-based ink, typically onto an aluminum alloy plate. This technique was devised by the British Robert Barclay who used it to print on tin in 1875. Later, in 1903, the American Ira Washington Rubel adapted it to print on paper.

Offset printing is similar to lithography. The image is applied on a form. Once revealed, the exposed parts of the mold begin to absorb water and repel the oily substance, ie the paint. These parts are called hydrophilic. The remaining parts, in turn, repel water and attract paint, these are called hydrophobic.

In this way, the ink is transferred exclusively to the hydrophobic parts of the mold, forming texts and images. The image is transferred from the roll with the printing plate to the offset roll, and from there onto the paper. The offset roller avoids a great wear of the forms and gives a greater uniformity of the ink.

With offset printing, a very high definition and a very good resolution of the printing are achieved, in addition, the printing quality is maintained even on surfaces that are not perfectly smooth, however, due to its large size and the need for a lot of maintenance, it is only recommended for very large productions.

linotype

Linotype, was a great advance in the history of printing, is a machine created by the German inventor Ottmar Mergenthaler in 1885, with it you can compose the text you want to print. Linotype together with letterpress printing was in common use in newspaper and magazine publishing from the end of the nineteenth century until the seventies of the last century.

The text is entered through a keyboard that contains ninety characters, the mechanism aligns the molds of the letters (matrices) in a line, this line is cast in a metal part in a process known as "hot metal typesetting". ». Matrices are saved to be reused. Linotype mechanizes a procedure that previously had to be done manually by operators placing letters, punctuation and spaces one by one.

This automation allowed the printing of newspapers with many pages and not just eight as was done previously. Linotype was widely used in the printing industry before the advent of photolithography and computer typesetting technology.

Laser printer

The laser printer was created by Gary Starkweather in 1973 and was marketed in the late XNUMXs by the Xerox Corporation. Prints made in this way are resistant to moisture, abrasion, and fading. The quality of this image is the highest.

A laser printer is one of the types of printers that allows you to immediately produce high-quality printouts of text and graphics on ordinary office paper. Like copiers, laser printers use the xerographic printing process in their work, but the difference is that the formation of an image occurs by direct exposure of the photosensitive elements of the printer with a laser beam.

3D Printer

The 3D printer is a machine designed to make copies of works in three dimensions, creating parts through a computer-generated design. It is normally used to make parts and components for industry and architecture. Currently its use has been extended to the production of all kinds of objects, casting molds, high-tech parts, food products, medical prostheses and many more.

3D printing can be done in multiple ways and using various materials, but any of them is based on the principle of layer-by-layer creation of a solid object. Many models are currently marketed: laser sintering, in which a dispenser deposits thin layers of powder of different metals as needed; stereo lithography, where a photosensitive resin is treated with ultraviolet light rays, causing it to solidify; of compaction, with a mass of powder that is compacted by layers.

The powder used is compressed in different ways, so they are classified as: 3D ink printers: compress the powder using agglomeration ink; 3D laser printers: a laser is applied to the powder so that it acquires different shades.

The future of printing

Thanks to the technological advances achieved in recent decades, it is now possible to distribute, market and read a book without the need to print it. The appearance of electronic paper or e-Paper and electronic books or eBooks allow the acquisition of books, magazines and other publications from the device itself, this greatly reduces production and distribution costs as well as being of great ecological value.

The massive use of the Internet has made it possible for a lot of information that was previously distributed through print media to now reach the interested party through web pages and email. This means that many specialists consider that, after having been fundamental in the development of humanity for more than five centuries, the history of printing finally comes to an end.

Here are some links of interest: